Fabric-Formed

Concrete Systems

It is an erosion-resistant, permeable concrete lining formed with a double-layer woven fabric, joined together by interwoven filter points (drains). Once pumped, the cobbled surface and relatively high coefficient of friction act to reduce velocity and wave run-up. The filter points provide for the relief of hydrostatic uplift pressure, increasing the system’s stability.

It is formed with a double-layer woven fabric, joined together by spacer cords on closely spaced centers to produce a mat of uniform thickness. Similar to traditional concrete slope paving, USM creates a solid, high-quality concrete lining with low hydraulic resistance for use in various lining and erosion resistance applications.

It is formed with a double-layer woven fabric, joined together into a matrix of rectangular compartments, each separated by a narrow perimeter of interwoven fabric and containing interconnecting high-strength revetment cables. Similar to precast block mats, once pumped, the ABM is designed to permit differential settling and block articulation.

It is custom fabricated to fit job site requirements. Inlet valves, attached by fabric flange to a slit in the surface of the bag, provide positive self-closure. Armor Bags offer an effective, adaptable, and economical alternative to the expensive and labor-intensive placement of rip rap—heavy boulders or large precast concrete blocks.

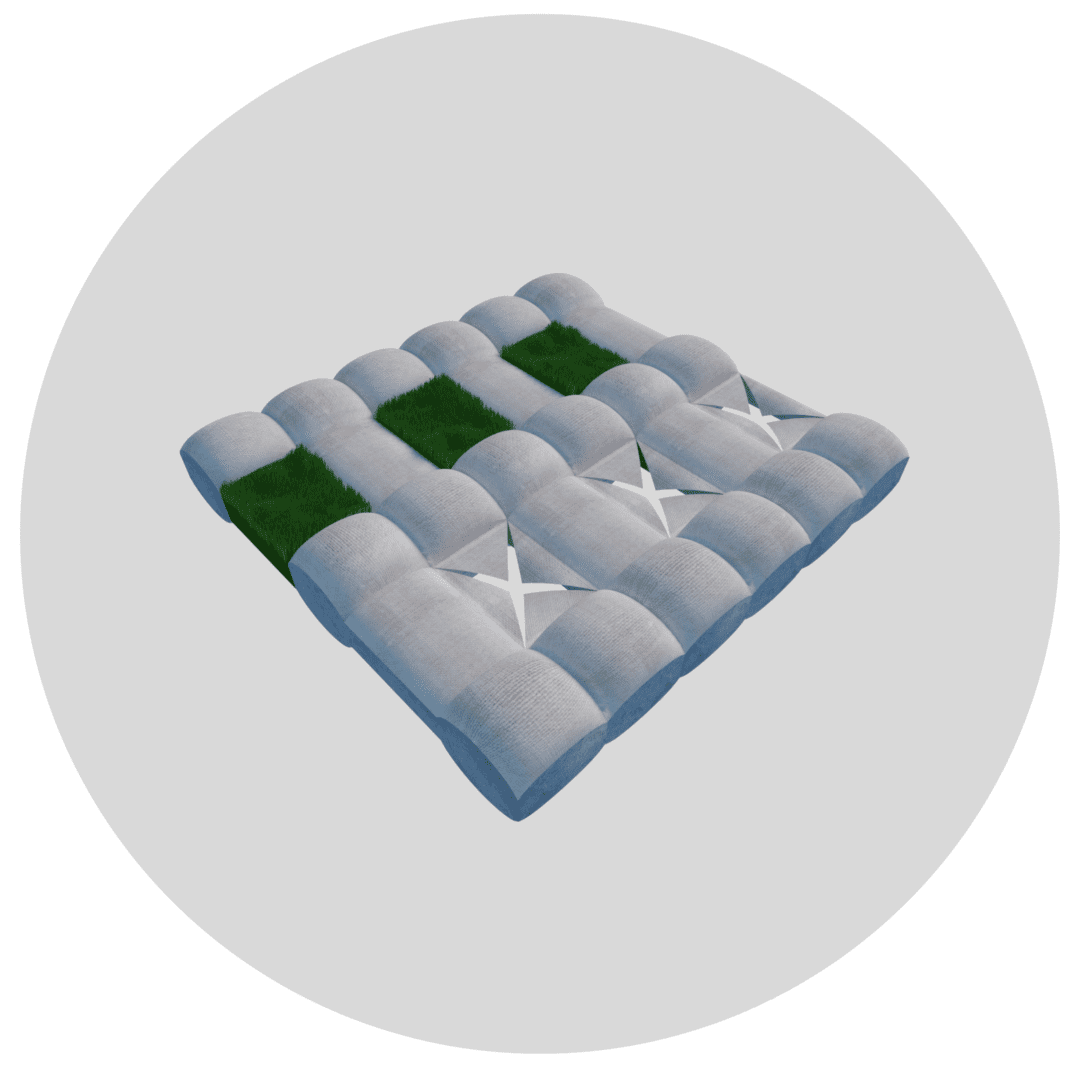

It is formed with a double-layer woven fabric, joined together into a matrix of rectangular compartments, each separated by open-cell voids to allow for re-vegetation. VegeMat can be selected with either a 25% or 35% open-cell voids that can be opened and filled with soil/seed, resulting in a system providing environmentally compatible protection with the necessary hydraulic, ecological and aesthetic features desired.

It is a new business unit founded to manufacture patent-pending marine concrete construction mattresses with our proprietary cost-saving process.